lt Density Index Measurement

made easy, accurate and reliable.

The simpleSDI silt density index meter makes Silt Density Index testing so easy that it's actually a pleasure. The time-consuming manual SDI test with it's errors and inaccuracies is a thing of the past.

Extremely Accurate: Microprocessor precision plus high resolution flow measurement provides silt density index test accuracy and repeatability far beyond hand testing.

Battery Powered and light weight for true portability. Up to 13 hours of testing between charges.

Performs SDI-5, SDI-10 and SDI-15 tests in both 100ml and 500ml sample sizes for more meaningful silt density index results and a complete picture of filter plugging.

Standards compliant 47 mm membranes for lowest cost, worldwide availability. Our membranes meet the new ASTM D4189-07 standard for silt density index testing.

SeaWater Compatible: Fully non-ferrous water path is compatible with sea water and other corrosive waters.

Continuous flow readout (mL/min) provides detailed information in real-time of the rate of filter plugging. This data can be used to manually plot Modified Fouling Index (MFI)-like data.

Built to the ASTM D 4189-07 standard for silt density index testing accuracy and repeatability greatly exceed the criteria of the silt density index standard.

Linear, precise pressure regulation for accurate results even on high SDI waters. Provides set-it-and-forget-it convenience.

Rugged, durable, reliable. Carefully selected components ensure years of trouble-free silt density index testing.

In-field calibration and repair. Modular design for easy field repairs. Sensor calibration is easy to perform in the field.

Audible alerts notifies the operator at the end of the silt density index test as well as if any errors have occurred.

Clear, easy to read LCD display prompts the operator through the test procedure and displays current test data while silt density index tests are underway.

simpleSDI Silt Density Index Tester

Technical Info and Specifications

Dimensions : Wide: 10.75 (273) Deep: 9.75 (248) High: 5 (127) Inch(mm)

Weight : 5 pounds

Electrical :

Battery Type : 6 Volt, 1.3 AH, Sealed Lead Acid (SLA)

Battery Life ; Approximately 5 years of typical usage.

Battery Capacity : Approximately 13 hours of testing.

Power Supply : 220VAC-9VDC 500 ma (international)

Water Supply Requirements

Feed Pressure : 35 psi (2.4 bar) minimum, 100 psi (6.9 bar) maximum*

Minimum flow rate : 1.4 Liters per minute at 35 psi at start of test

Solids : Free of large solids. Filter to 50 micron minimum.

(Cleanable 50 micron filter included in kit)

*A booster pump kit is available for use on water supplies with insufficient pressure.

Tests Performed :

SDI-5 : SDI-5, 100ml and 500ml sample volumes

SDI-10 : SDI-10, 100ml and 500ml sample volumes

SDI-15 : SDI-15, 100ml and 500ml sample volumes

Flow measurement : Continuous real-time display in mL/min

Membrane Filter Info :

Polymer : Mixed Cellulose Ester (nitrocellulose)

Form : 47 mm dia disc

Pore Size : 0.45 micron

Surface/Color : Plain/White

Thickness : 145 micron

ASTM D4189-07 : Compliant

simpleSDI is compliant by exemption

Emission: EN 61000-6-3:2007

Immunity: EN 61000-6-1:2007

What is SDI?

The Silt Density Index (SDI) test is a means of quantifying the amount of particulate contamination in a water source. The test was specifically developed as means of predicting the rate of colloidal and particulate fouling of Reverse Osmosis (RO) membranes.

Description of the silt density index test

The silt density index test described in ASTM 4189-07 is performed using a .45 micron, 47mm diameter filter. The water to be tested is supplied to the filter at a constant pressure of 30 psi. The test involves measuring the time it takes to collect a 500 ml sample through the filter at the start of the test and comparing it with the time it takes to collect a 500ml sample after water has flowed through the filter (at 30psi) for 15 minutes. The sample times are applied to the formula below to obtain the SDI15 value.

The resulting value, SDI-15, indicates the plugging of the membrane in percent-per-minute. Accordingly, the maximum SDI-15 value is 6.7. (100÷15=6.7) An SDI15 value greater than 5 is generally considered too high to be meaningful (75% plugging).

On waters with high SDI, it’s often useful to measure the SDI at 5 and 10 minute intervals. The resulting values, SDI-5 and SDI-10 can provide a better indication of the rate at which the membrane is plugging. For example, if you obtain an SDI5 of 15, there’s no point in taking the time it takes for an SDI15 test since you’ve already achieved 75% plugging (15 x 5=75). In this case, the water being tested is simply too high in colloidal or particulate matter to obtain a meaningful result.

Limitations of the manual Silt Density Index test

Information on silt density index (SDI) testing.

- What's new in the 2007 version of ASTM D4189?

- How do the membranes from different manufacturers compare?

- Which side of the membrane is the feed side?

- Why does it matter which side of the membrane is used as the feed side?

-

What's new in the 2007 version of ASTM D4189?An update, to the standard for Silt Density Index testing (ASTM D4189-07) was released in July of 2007. The update addresses a deficiency and in our opinion corrects an error that has existed since the standard was first released in 1989.

Perhaps the most critical component of the SDI test is the membrane filter used in the test. Previous versions of the standard had defined the membrane as follows:6.2 Membrane Filter, 47 mm in diameter, gridded, and with a mean pore size in the range 0.45 +/- 0.02 μm, inclusive. Use only filters that are packaged in the same orientation.

Note that the type of membrane, that is, the polymer, was never specified. While standard practice has been to used mixed cellulose ester membranes, the lack of a specification meant that membranes of other polymers could be used. Since membranes of different polymers have widely varying permeability characteristics this is a potentially huge source of variation in test results.

The error in the old standard was the designation to use a "gridded" membrane. This never made sense and in conversations with water professsionals all around the world I never encountered one who was using "gridded" membranes. This is significant because the process of "gridding" the membrane affects the surface of the membrane making it more permeable. This obviously introduces an unwanted and unneeded variable.

Both of these issues have been corrected in the new standard. Section 6.2 has been expanded to include the following definitions of the membrane filter properties:6.2 Membrane Filter:

6.2.1 Membrane—white hydrophillic, mixed cellulose nitrate (50–75 %) and cellulose acetate (MCE).

6.2.2 Mean Pore Size—0.45 μm.

6.2.3 Diameter—47 mm nominal, plain.

6.2.4 Thickness—115–180 μm.

6.2.5 Pure Water Flow Time—25–50 seconds/500 mL.

6.2.6 Pressure—91.4–94.7 kPa (13.3–13.8 psi).

6.2.7 Bubble Point—179–248 kPa (26.0–36.0 psi)

-

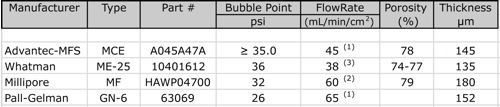

How do the membranes from different manufacturers compare?For many users, the Millipore membrane has been the "standard" membrane for silt density index testing. If you Google silt density index you'll even find a reference or two that actually states that the test is to be performed with a Millipore membrane. Since the characteristics of the membrane has a profound effect on the results, we prepared a comparison of the leading membranes.

This comparison reveals some interesting differences. Especially interesting is the relatively "loose" characteristics of the Millipore membrane which is so widely used. The "loose" designation is supported by the relatively low bubble point and a corresponding high flow rate of the Millipore membrane. For use in SDI testing, "looser" translates to less consistency and less reliable results. Given the many variables in the silt density index test, adding membranes as a variable doesn't make sense. We don't have any experience with the Whatman membranes, but based on their specs they look like a viable option. And of course, we recommend Advantec-MFS membranes without reservation.

-

Which side of the membrane is the feed side?The membranes used for silt density index measurement are asymmetrical. This asymmetry means that one side is slightly shinier than the other. The shiny side of the membrane has pores that are smaller than the "dull" side. For consistent and the most accurate results, you should always use the "shiny" side of the membrane as the feed side.

-

Why does it matter which side of the membrane is used as the feed side?Because the membranes are asymmetrical, the pores are smaller on the shiny side. Using the side with the smallest pores ensures that the particle size retained by the membrane are more consistent with the rating of the membrane. In practical terms, the difference is small, but if you want consistent results, its worth the effort.